The Design of Injection Moulds is done on 3D environment with the use of the latest CAD software's. The design systems are fully integrated into the manufacturing process. Part data is received from the customer in either of the following formats - Pro Engineer part files, STEP, IGES output from any other software. The data could be exchanged through email & CD's.

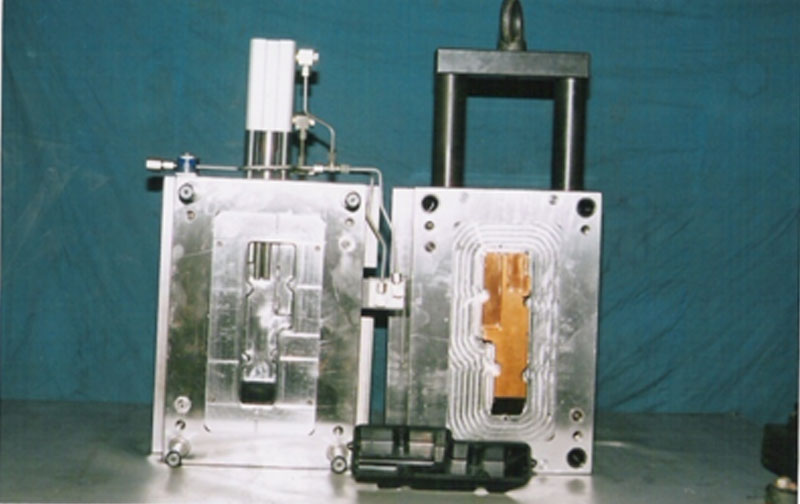

All the moulds undergo rigorous testing before dispatch. Sample articles with measured dimensions are sent to the customer for approval and functional testing. Recorded moulding parameters enable immediate production start up after delivery of the injection moulds.

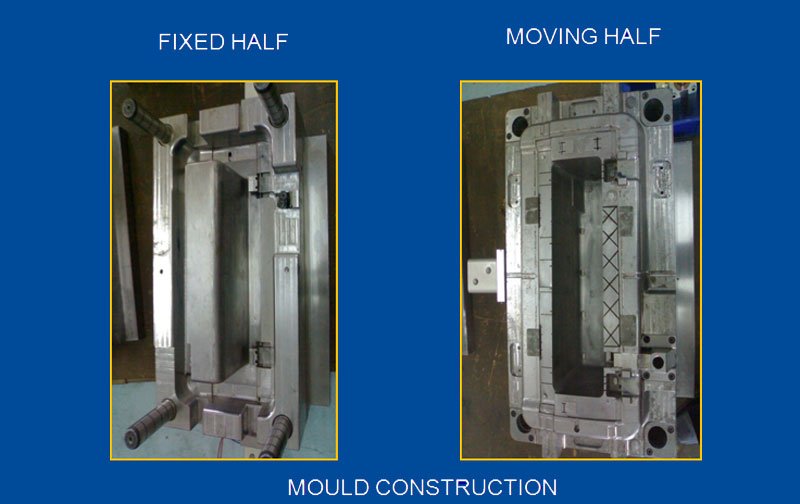

The art of mould developing comprises customer input and the requirements which are delivered to the manufacturing team through reviews and action plans to achieve zero failure delivery commitments.Codes and programs generated by eminent crew of programmers were transferred to the CNC team, where the Execution of steel cutting is done through world class cutting technology. We utilize international standard steels, preferred and accepted globally.

The tool development traits were validated through spotting and trials. The process status is transparent by up to date tracking offered to the customer. The manufacturing team also handles the quality of execution and extraction of jobs which were outsourced.

To know more about Services and Enquiries Click here